Comparative Analysis of Warehouse Automation Tools: Your Practical Guide

Chosen theme: “Comparative Analysis of Warehouse Automation Tools”. Explore unbiased comparisons, real stories, and decision frameworks to select technology that truly fits your operation. Join the discussion, share your evaluations, and subscribe for ongoing deep dives and actionable tools.

What Counts as Warehouse Automation Today

Software Backbone: WMS, WES, and WCS Compared

A clear delineation between WMS, WES, and WCS prevents overlapping responsibilities and costly confusion. Compare scheduling logic, order orchestration, latency tolerance, and exception handling before pairing any software with physical automation.

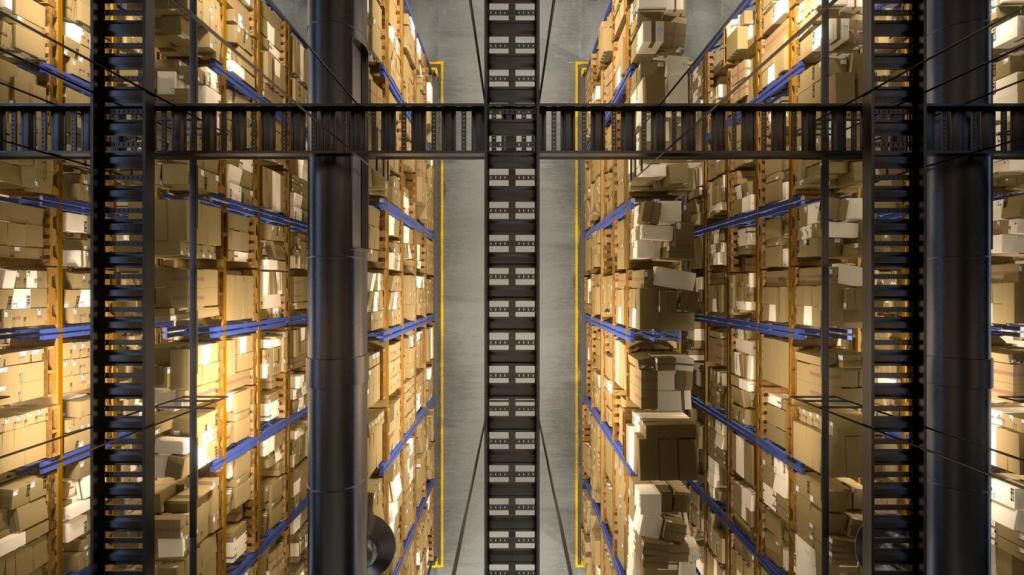

Robots and Storage: AMRs, AGVs, and AS/RS in Context

AMRs excel in dynamic, human‑heavy environments, while AGVs favor fixed paths and predictable flows. AS/RS systems deliver dense storage and high throughput but demand upfront layout discipline, redundancy planning, and precise integration interfaces.

People‑Centered Automation: Voice, Vision, and Pick‑to‑Light

Voice‑directed and light‑directed picking often lift accuracy and morale when introduced thoughtfully. Consider accent variability, lighting conditions, battery management, and ergonomic cues to ensure measurable gains without overwhelming teams during ramp‑up.

Total Cost of Ownership Checklist

Account for integration, commissioning, safety validation, training, spares, software subscriptions, network upgrades, and facility modifications. Include downtime risk, ramp curves, and decommissioning costs to avoid flattering, short‑term illusions.

Performance Metrics That Matter

Compare tools using stable baselines like lines per labor hour, order cycle time, pick accuracy, and uptime. Normalize for shift length, SKU mix, and seasonality to keep conclusions fair and transferable.

Case Snapshot: A Regional 3PL’s Forklift‑to‑AMR Transition

One operations lead shared that phased AMR adoption cut travel time dramatically without redoing racking. The surprise expense was Wi‑Fi hardening, yet the win was safer aisles and steadier throughput during peaks.

Scalability, Flexibility, and Peak Readiness

Look for autonomous fleet managers that coordinate traffic, charging, and task allocation. Test behavior under dense crossings, blocked aisles, and battery scarcity to compare resilience instead of demo‑floor polish.

Safety, Compliance, and Workforce Experience

Compare tools against relevant safety guidelines and local regulations. Review speed limits, separation zones, fail‑safes, and functional safety claims, then validate with trials and documented, repeatable procedures.

Safety, Compliance, and Workforce Experience

Collaborative robots shine when tasks are redesigned, not bolted onto old routines. Compare handoff points, visual cues, and exception playbooks so people stay confident, informed, and genuinely empowered.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.